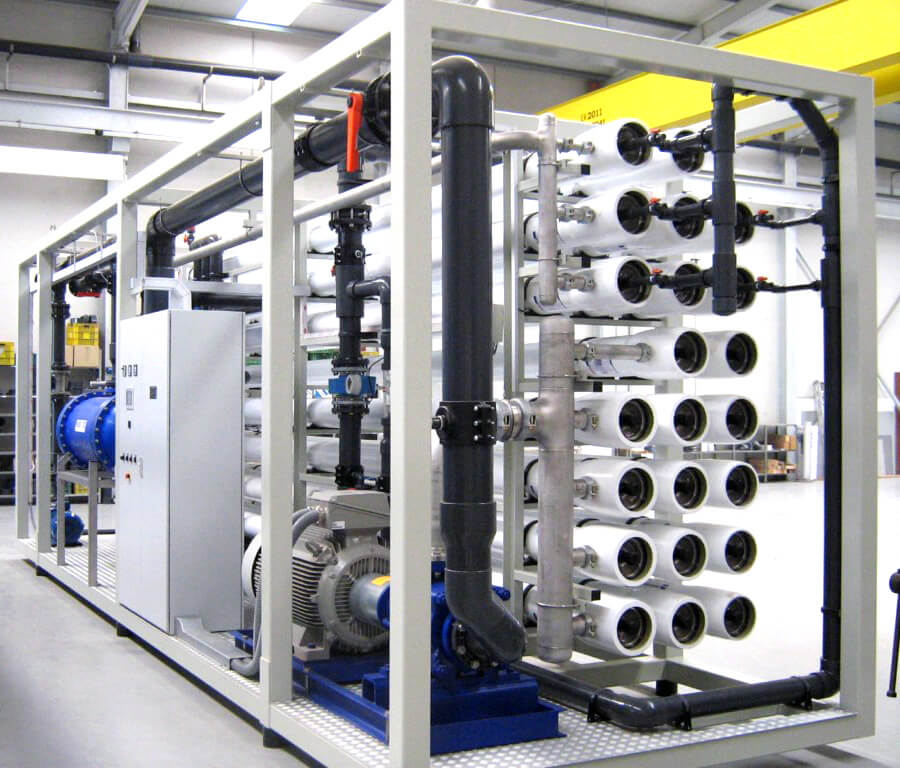

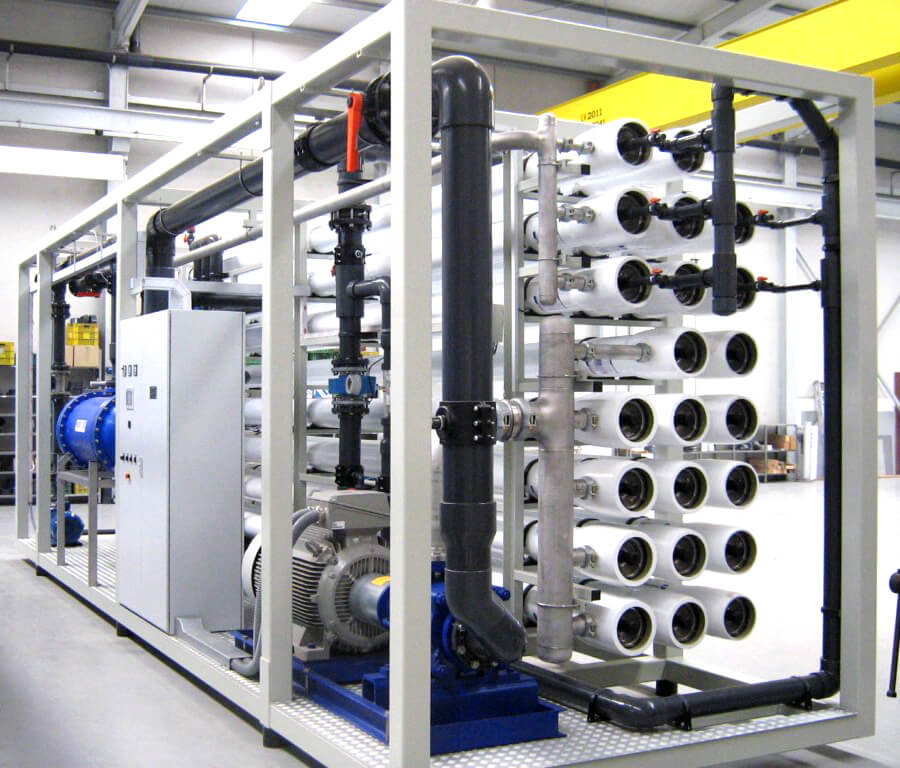

HRO Compact transportable plants

HRO Compact transportable plants

Designed in compact modules that are easy to transport both by road and by sea. The design consists of frames holding all the plant’s equipment, measurement and control instruments, electrical control box, plus the pressure vessels with reverse osmosis, sand filtering and micro-filtration membranes.

The frame is built out of structural Carbon Steel pieces protected with an anti-corrosion treatment finished in shiny aliphatic polyurethane so that the assembly can withstand water and damp environments. It also includes an anodised anti-corrosion aluminium sheet floor that makes it easier to operate and maintain the equipment.

The frame is structurally calculated to support all the equipment on full load, so the complete equipment can be transported from our factory to its definitive site and undergo any subsequent moves if necessary.

ECO – Modular plants

We supply modular facilities fully mounted on compact frames that are easy to install and transport. They adapt perfectly to small spaces given that the sand filtering module is physically separate from the osmosis frame. Designed to facilitate the actual maintenance work on the equipment and make it easier to operate. Programmed to work automatically, according to the customer’s needs.

ECOBOX – Autonomous plants in containers

ECOBOX – Autonomous plants in containers

The EcoBox plants have been designed to reach places where it is not possible to install equipment inside a building. All the necessary components integrated into a container that is easy to access for maintenance, even including a feeder pump for the system should this be necessary. Total automated sand filtration by means of polyamide pneumatic valves and chemical cleaning station with independent circuits to maintain membranes.

Productions of up to 1,100 m3/day of excellent quality water coming from salty water in a single standard 12 m container. It does not require any civil engineering, just a firm base. Easy to transport and change location when necessary.

For larger equipment, we have a sheet metal enclosure making the most of the actual module structure so that the assembly is closed in under a pitched roof. All the additional structure is pre-fabricated and quick and easy to assembly on site, as well as perfectly transportable.

Fresh water from the sea

Despite the enormous quantity of water that exists on the Earth, availability of water that can be used directly is very low, particularly in places where there is little rainfall and a growing need to obtain fresh water for domestic, agricultural or industrial use from salt water.

Therefore, obtaining drinking water from seawater is a priority target for progress in arid countries.

Reverse osmosis technology give the highest level of separation for dissolved salts, suspended solids and micro-organisms.

We manufacture facilities for desalination of salty water and seawater to be used in irrigation, human consumption, demineralised water for industrial processes or ultrapure water for labs.

We use the latest generation of membranes, with high reject and low pressure, giving high water quality and low operating costs.

Our facilities optionally offer energy saving systems such as high yield pumps, energy recovery systems, frequency variators to adjust consumption, different degrees of automation, operating facilities from manual control right up to complete automation with distributed control systems, SCADA and remote control via PC:

We offer a wide range of possibilities, scalable equipment from less than a cubic metre of daily production up to modules with unitary production of 4,000 m3/day that can be fitted in parallel to develop projects to any scale.

The technological progress in the membrane materials and the experience in designing desalination plants using reverse osmosis currently make it possible to extract large quantities fresh water from the sea at a competitive price for agricultural, industrial or human consumption uses.

Characteristics of desalination plants

Features of reverse osmosis desalination plants. SEAWATER

| Type of Plant | HRO-67-M (P) |

HRO-220-M (P) |

HRO-450-M (P) |

HRO-890-M (C) |

HRO-1360-M (C) |

HRO-1780-M (C) |

HRO-2230-M (C) |

|---|---|---|---|---|---|---|---|

| Production | 30m3/day | 100m3/day | 200m3/day | 400m3/day | 600m3/day | 800m3/day | 1000m3/day |

| Electrical C. | 4,6(1) | 4,1(1) | 4(1) 2,7(2) 2,1(3) | 5,4(1) 3,7(2) 2,7(3) | 4,9(1) 3,6(2) 2,6(3) | 4,9(1) 3,3(2) 2,5(3) | 4,8(1) 3,2(2) 2,4(3) |

| Yield | 45% | 45% | 45% | 45% | 45% | 45% | 45% |

| Nº Frames | 1 | 1 | 1 | 1 | 2 | 2 | 2 |

| Dimens.(LxWxH) | 4x1x2 | 6×1,5×2,2 | 7×1,5×2,2 | 10×2,5×3 | 10×2,5×3 | 12×2,5×3 | 12×2,5×3 |

(1) No energy recovery system (2) Includes energy recovery system (turbo) (3) Includes energy recovery systems (isobaric chambers)

(P) Includes volumetric pump (C) Includes centrifugal pump

* The data in the table is merely a guide. Please enquire about other equipment sizes.

| Type of Plant | HRO-10-R | HRO-67-P | HRO-200-P | HRO-660-P | HRO-1330-P | HRO-2660-P | HRO-5330-P |

|---|---|---|---|---|---|---|---|

| Production | 10m3/day | 50m3/day | 150m3/day | 500m3/day | 1000m3/day | 2000m3/day | 4000m3/day |

| Electrical C. | 1,9 | 0,9 | 0,8 | 0,6 | 0,6 | 0,6 | 0,6 |

| Yield | 33% | 75% | 75% | 75% | 75% | 75% | 75% |

| Nº Platforms | 1 | 1 | 1 | 1 | 1 | 2 | 4 |

| Dimens.(LxWxH) | 1,4×0,6×1,8 | 3×0,9×1,8 | 6x1x1,8 | 7x2x2,8 | 9×2,5×2,8 | 9×2,5×2,8 | 9×2,5×2,8 |

* The data in the table is merely a guide. Please enquire about other equipment sizes. ** The letter after the plant model refers to M= seawater, R:=municipal tap water, P=well water.